Quality Control

Changwen is a trusted stainless steel cookware supplier in China. We have extensive experience in manufacturing a wide range of stainless steel cookware. All of our products are made of high-quality stainless steel materials. Therefore, you can be sure of the corrosion and oxidation resistance of the products, extending their service life.

When looking for the right custom cookware manufacturing, always trust Changwen Company. We use a strict quality management system from raw material selection to product testing. We have a professional and skilled team that produces custom cookware manufacturing products of superior quality.

At Changwen, you can find the best stainless steel pots and pans for your business!

Home > Quality Control

Cookware Quality Control

Our production is strictly following internationally recognized quality control system and testing requirements, for example, BSCI, FDA, LFGB, etc.

We implement a 100% whole-process monitor from the status of untreated raw materials — bonding & brazing into shapes — accessory production — integrated component installment — package printing, and eventually to the status of well-packed finished products. Furthermore, every workshop runs with its own QC stuff for random manual inspection to a requested proportion.

Our double measures ensure products, which are produced in our factory, to reach over 90% product qualification ratio, and have returned us wide recognization from worldwide importers, distributors and retail chains.

Cookware Process

Every pan and pot will go through at least 8 meticulous processing steps before it becomes qualified cookware.

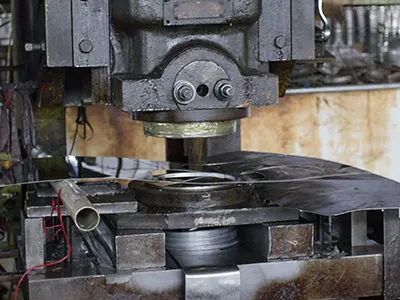

1. Cold press with precision

2. 1st wash to remove grease

3. Rim processed to perfection

4. Hand polishing to refine

5. Sandblasting to improve adhesion

6. 2nd cleaning to remove grains

7. interior & exterior coation

8. Final handle assembly

Cookware In-Process Quality Control

Under ISO quality control system, all processes from raw material incoming to finished product, inspection are controlled strictly by our QC team in periodically.

Surface Inspection

The surface of each pan or pot is carefully inspected before & after molding to ensure there’s no bubble or scratch.

Bending strength test of handle fixing device

Put the weight into the pot or hang the weight at the end of the handle to test the bearing capacity of the pot and handle.

Dimension Measurement

A caliper & dilatometer are used to check if the cookware dimensions, rim thickness & bottom concavity meet the designated requirements.

Bottom Striking Test

After covering the bottom, our worker will strike the bottom of every pan or pot with a small copper hammer to make sure it adheres firmly.

Final Inspection

Every part including the handle & the lid is carefully tested & inspected after assembly. No scratch, grease or unsightly welding spot is allowed.

Non-stick Coating Test

Coating testing machine & 3M 898 adhesive tapes are used to check the thickness, hardness & adhesion of nonstick coating every 1 hour.

Life test

The service life of the coating in real life can be obtained by simulating the service time of the pot through friction.

Heat-resistant Test

To test the heat-resistant performance of the non-stick coating, we put the pan or pot into the thermotank and heat to 250℃.

Salt Spray Test

Anti-corrosive performance of the non-stick coating is tested with 5% NaCl. The solution is heated for 7 hours.

Magnetic inspection

(only applicable to electromagnetic cooker): test with magnet. If there is no magnetism, the test fails.

Quality Assurance

• Customer’s satisfaction is our pursuing goal.

• Customer-oriented is the principle of our services.

• Our core value and core competence is according to effective, convenient and cost-controlled customer services.